However I ordered a USB to PS2 adapter a while back and finally got around to using it – it was going to allow my inlaws to use their old keyboard and mouse with the new computer I’m sending them. Unfortunately I couldn’t get it to work. I tried it on several different computers and in both XP and Linux Mint. It was recognized as a USB hub but the keyboard and mouse wouldn’t work. Power was getting through to the mouse (as evidenced by the red light of the LED).

Rather than send it back (It cost all of $1.94) I thought it would be interesting to see how and why it failed. At least in so far as my limited electronics knowledge could determine.

Part# 2855 which is now discontinued and completely gone from their website. I bought it in August of 2011.

I suspect that it was discontinued for exactly the problem (I think) I discovered.

Fun with a box cutter.

There’s a circuit board.

This is where it gets somewhat interesting. Black to VDD, Red to DATA, Green to CLK (Clock) and White to GND.

Notice I tried to scrape away the epoxy to verify that there was actually a chip under there. I saw bits of metal so I assume so.

The PS2 pinout from Wikipedia’s article. Pin 5 is Clock and Pin 1 is Data.

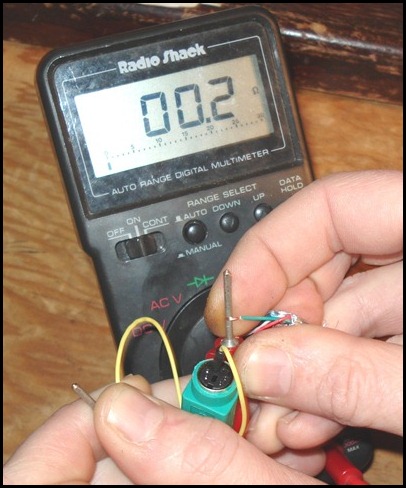

Jumper in pin 5 position, which should be CLK (Clock)

Showed continuity to the red wire which was soldered to the Data tab on the circuit board.

Jumper in pin 1 position, which should be Data.

Shows continuity to the green wire, which was soldered to the CLK (Clock) tab on the circuit board.

Here’s a shot taken by my loving wife that shows the test, this time with the green (mouse) PS2 connector. Jumper is in pin 1 (DATA), green wire (Soldered to CLK on the circuit board) shows continuity.

I really need to get some grabby probe tips for my VOM.

So unless I am mistaken (and it’s always possible I am, let me know if you see an error in my analysis), the problem with the adapter is that the CLK and DATA wires are reversed. While the adapter doesn’t work I think I had $1.94 worth of fun looking at the problem.