These are stamped with the Kanji (Chinese character, used in Japanese) for water, "mizu".

As always these earrings are available on Etsy...

See my mistake? The one in the center would have made a backwards "om". A quick flip and I milled the correct die cavity on the right...I do this more often than I admit...

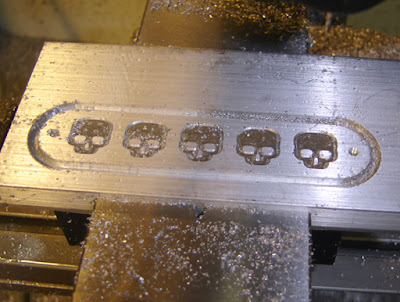

A bunch of dies, biohazard, celtic knot, om, pi and mizu. Milled into 6061 aluminum. A very quick way of making new earrings.

A blurry closeup of the celtic die and the stamping.

My new Mk2 ring mandrel. I decided that chucking it in the 4 jaw would allow me to dial it in when mounted on the rotary table so that any engraving/milling would be true to the periphery of the ring.

The parts, conical washers and a split, shouldered, bushing (this one is size 8)

The conical washers force the bushing to expand when the screw is tightened. I have plans for the Mk1 Taig version here.

See my mistake? The one in the center would have made a backwards "om". A quick flip and I milled the correct die cavity on the right...I do this more often than I admit...

A bunch of dies, biohazard, celtic knot, om, pi and mizu. Milled into 6061 aluminum. A very quick way of making new earrings.

A blurry closeup of the celtic die and the stamping.

My new Mk2 ring mandrel. I decided that chucking it in the 4 jaw would allow me to dial it in when mounted on the rotary table so that any engraving/milling would be true to the periphery of the ring.

The parts, conical washers and a split, shouldered, bushing (this one is size 8)

The conical washers force the bushing to expand when the screw is tightened. I have plans for the Mk1 Taig version here.