Cleaned up the last (or first) terminal. It had pretty bad pitting but not in the area of contact with the battery.

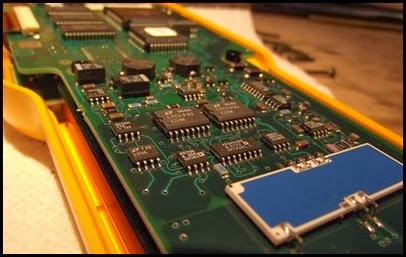

Just some more PCB pics.

I bent up a crude replacement for the “SPRING, BATTERY” from .040 music wire, by hand. Yes, I’ll probably buy a replacement from Fluke but they only handle orders over the phone and that’s my least favorite way of ordering replacement parts. Just let me shoot you an email, Fluke. Better yet, let me send you a link to this 2 part blog post.

Dear Fluke,

I need two of MP8 “SPRING, BATTERY”, two of MP9 “COVER, BATTERY (OVERMOLDED)” and two of BP1 “UNNAMED FLAT SPRING BATTERY CONTACT THAT CORRODES IF YOU GLANCE AT IT WITH A WRY EXPRESSION”.

Love,

Pregnant Walrus Man

The signature will make more sense in a couple of pictures. Anyway, I digress.

Seems to work.

Three working meters!

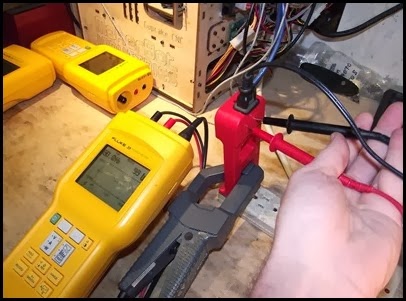

My test setup. A 60 watt bulb in a light plugged into a Tekpower M920 AC Line Splitter. I bought it because it was the cheapest one on Amazon that would ship via Prime, the more expensive ones didn’t seem like they had better functionality or quality.

Clamp on the X1 coil, leads (not Fluke leads, I didn’t get this type with the meters…) held against contacts on the line splitter. I’d love one of these that just had banana jacks for voltage.

I tested all three meters, just checking Volt, Amp and Watt readings. They all agree to within .3V, .01A and 1W. Not bad. I imagine they are all out of calibration though.

I look like a pregnant walrus. Felice always takes flattering pictures of me.

So this is a better shot of the test setup.

Now let’s test a APC ES-550 UPS! Fun!

On line power.

On battery power. A square/trapezoid wave with lots of ripple.

Line voltage, 2.7% THD.

Battery voltage, 48.5% THD.

How about a Cyber-Power 585AVR? Line voltage.

Under battery power.

After a minute it dropped 2 volts and then stayed pretty stable. I didn’t run the test for longer as this was more of a lazy Sunday entertainment.

In any case it seems like the meters work. Yay me.