Just cleaning out my latest picture folder. What I’ve been up to since the last catching up post a month or so ago...

We had a

record storm! The most snow since we moved here back in the ‘90s. It lasted for days and completely paralyzed the Willamette valley.

The power went out one morning as the weather transitioned from snow to rain and trees fell across lines. We coped by playing

Qwirkle.

Henry made a FM radio with his

Snap Circuits Kit

so he could listen to the radio while waiting for the power to come back on. Not a bad emergency plan I suppose.

The next weekend or so I went to the

hamfair with my friends Gregg and Bill. They are crazy hams. I was on the hunt for test equipment and vintage computing stuff.

Gregg and I filled his Prius trunk. Bill was completely disciplined and bought nothing.

I bought this lovely fluke bench multimeter.

An audio sweep generator, multimeter (broken but I will have a post about fixing it soonish) and an EMF meter to drive my hippie friends crazy with.

Gold! I paid a quarter a piece for these lovely vintage CPUs.

Heathkit and Zenith together.

My new Color Computer II!

And a pair of Micro Color Computers, one of which is broken.

I was getting the

Continostat out (long story for another post) and found this micrometer hiding under a bench.

Then it was the weekend of the

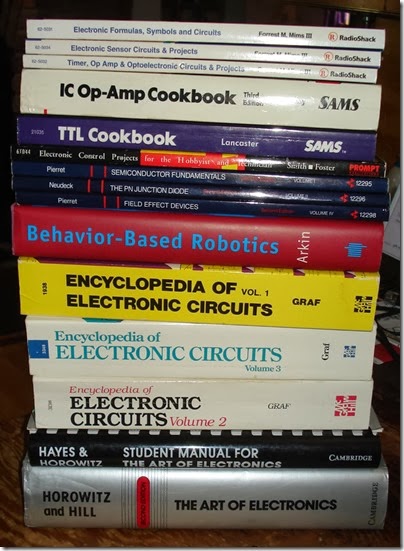

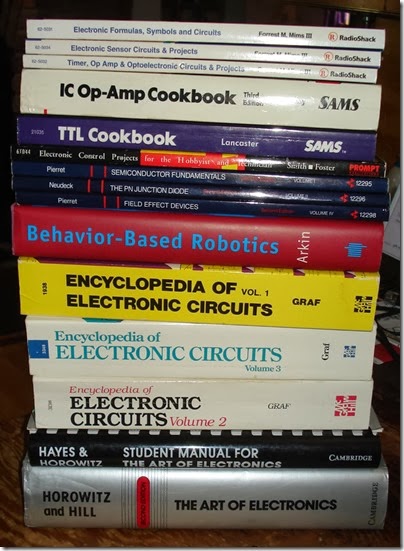

Benton County Friends Of The Library Sale. I was extremely disciplined and only bought this small stack of books. This is hilarious considering what comes next.

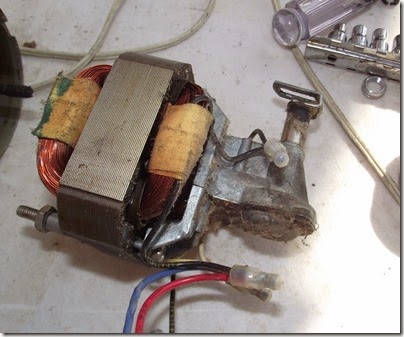

The next weekend had an estate sale for a man named Chris McGlothlin. I don’t know anything about him other than that I wished I’d met him when he was alive. Nobody I know knew him, and the internet has no mention of him (other than being listed as “missing” in a picture of some EE’s at OSU). Anyway over two days I bought piles of electronics components, kits, parts and tools…and books…

A function generator

My new favorite thing. An extremely nice power supply.

Way too many books. But many good books.

And a very important piece of history.

But this is where I will impart a life lesson (beside the obvious lesson about hoarding):

At the sale on Friday I talked to a young guy who had just bought a hot air soldering station at the sale (wish I had seen it first, but he wished he had seen the power supply before I did as well…as such things go). Anyway when I got home I found that among the random parts I had bought in a box of crap were some tips for his soldering station.

The next day (yes, I went back as they were willing to make very good deals, hence all those books) I was talking to a woman who mentioned that her son had bought the hot air station. So I told her to tell him to email me so I could give him the parts (they would do me no good). Turned out she was the landlady of the house the estate sale was at…

You see where this is going don’t you?

Yes, I met the young fellow a few days later and gave him his parts and he let me take all the books (all the books I wanted) that were left in the house, as they had been abandoned by the family.

The lesson? Pay attention and be nice. I should do that more often.

Let me just say that Felice is very understanding.

I got a little hardware as well.

I told you it was funny that I was so disciplined at the book sale…I am a book magnet. I did get give away a pile to Gregg almost immediately, so it’s not quite as bad as it looks. Ok, it is as I also got a bunch of Nuts & Volts and other electronic hobby magazines.

And finally, I fixed a spatula (turner). I don’t know where to get these style anymore with the thin springy stainless steel blade, so I fix them when I have to.